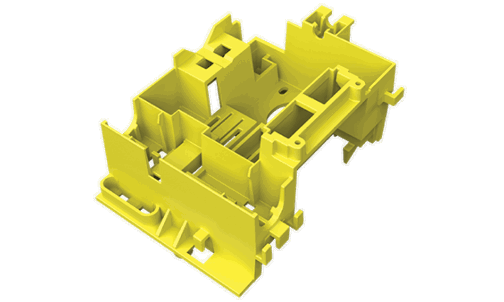

Discover injection molding solutions

Efficient Plastic Part Production Using Custom Molds. We Support The Entire Process From Tooling

To Low-Volume Production With Consistency And Speed.

Excellent Repeatability And Broad Material Compatibility For Various Applications.

Materials

General : PC, PC+ABS, ABS, PE, PP, PS, PET, POM, PA6, PA66, Etc

Reinforced : GF%+, CF%+, PEEK, PPSU, Ultem Etc

Clear : PC, PMMA, ABS, Etc

Soft : TPU, TPE, TPS

Size

Part Max Height 350X400X150 (Core Max 640X520X280)

Part Max 400X520X60/Part Min 2.0X2.0X1.0

The Available Size Will Be Confirmed By Undercut Existence

Color

Various Resin Colors Available

Custom Color Matching

Pantone Color Code Or Chip Is Mandatory

Quick Turn(Mobile Phone Size)

- Simple7 Day

- Normal10 Day

- Complex13 Day

Tool Material & Life Cycle Time

AL(5K) , P20 (KP-4M)-(10K ), NAK80(50K) , H13 (SKD-61)-(80K)

Get custom plastic parts within days. Request an online quote.

Injection molding is a manufacturing process that consists of filling a metal mold cavity with liquid plastic resin, which then cools and forms a plastic part.

It’s most often used for the manufacturing plastic parts at scale due to its low material waste and low cost per part. It’s an ideal manufacturing process for industries like medical devices, consumer products, and automotive.

Plastic Molding Capabilities

Our basic guidelines for plastic injection molding include important design considerations to help improve part moldability, enhance cosmetic appearance, and reduce overall production time.

| US | Metric | |

| Size | 18.9 in. x 29.6 in. x 8 in. | 480mm x 751mm x 203mm |

| Volume | 59 cu. in. | 966,837 cu. mm |

| Depth | 4 in. from parting line | 101mm from parting line |

| Up to 8 in. if parting line can pass through the middle of the part | Up to 203.2mm if the parting line can pass through the middle of the part | |

| Projected Mold Area | 175 sq. in. | 112,903 sq. mm |

Tolerances: Typically, Protolabs can maintain a machining tolerance of +/- 0.003 in. (0.08mm) with an included resin tolerance that can be greater than but no less than +/- 0.002 in./in. (0.002mm/mm).

Plastic injection moulding and mould production

General information

We are specialists in the injection moulding of small series.

We use moulding materials such as epoxy and polyester, which are filled with metal, quartz sand and other fillers. We also use low/medium melting point alloys to produce simple structural moulds. This type of mould has a simple manufacturing process, a short cycle and a low price. This is ideal for small and medium batches. Quantities from 500 to 5,000 parts can be produced with single or multiple cavities. We also offer polishing and texturing for the surface of the moulds.

For large batches, we use the standard mould process.

Materials for injection moulding

Here you will find a list of our standard materials for injection moulding. If you require customised information, please contact us.

POM, PC-ABS, ABS, PET, PA66, PMMA, PA-GF, PPS, HDPE, PP, LDPE, PS, PBT, PS-PPE, PC, TPE, PC-GF, TPV

Component finishing

- Polishing

Polishing is used to reduce the surface roughness and to obtain a smooth, mirror-like surface. - Laser engraving

A surface treatment process based on optical principles. - Texturing

Is a surface treatment of moulds which improves the beauty and strength of the surface. - Pad printing

A printing process in which text, graphics and images are applied to irregularly shaped surfaces. - Individual colour coating

The use of an air pressure gun enables the colourant to be applied evenly and efficiently to the surface to be treated. - Screen printing

The screen printing process is the method of choice in advertising technology and labelling, in textile and ceramic printing, for high-quality effect finishes and in industrial printing. - Heat treatment

Heat treatment results in a change in the chemical composition and structure in the solid state.

Discover new possibilities

You can directly send the following data formats: Catia, NX, STEP, IGES, PRT, SLDPRT, DXF, and DWG.

We can convert CAD data formats so they are usable for production. Email:service@goldenrapid.com

Contact us

Get instant quotes for cost-effective solutions : From confidential design-to-product services to fast delivery, we empower innovators with precision and speed. Contact us now!

Phone: +86 0592 373 1111

E-mail: service@goldenrapid.com