Discover Sheet Metal Fabrication services

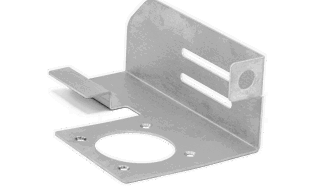

Mass Production Of Metal Components With High Durability Using Stamping Dies.

Suitable For Brackets, Terminals, And Structural Frames.

Scalable For High-Volume Needs, Reliable Dimensional Accuracy.

Materials

Iron Plate

Cold Rolled Steel Sheet

Hot Rolled Steel Sheet

AL, Sus, Copper

Size

Part Max : 1,000x300x200

Quick Turn(Mobile Phone Size)

- Simple2-3 Day

- Normal7 Day

- Complex2-3 wksProduction

Progressive Tool

Fabrication Capabilities

Manufacturing technologies

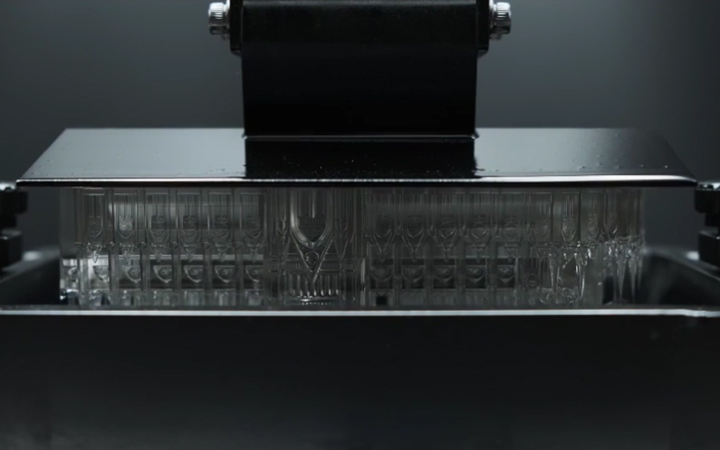

Our range of services includes laser metal cutting and bending for the production of sheet metal parts. The automated cutting process we use guarantees high precision and quality parts. All parts can be reworked according to your requirements: This includes coating, heat treatment and other processes.

Processable metals

The following materials are available: Aluminium, stainless steel, brass, copper, alloy steel, bronze, titanium and carbon steel.

Tolerances

We offer different tolerance standards according to ISO 2768 (standard, fine) and ISO 2768 (grade 8, 7, 6). Please contact us for detailed information and customised solutions.

| Detail | Dimensional tolerance (mm) |

| Edge to edge (single surface) | 0,127 mm |

| Edge to hole (single surface) | 0,127 mm |

| Hole to hole (single surface) | 0,127 mm |

| Bend to edge/hole (single surface) | 0,254 mm |

| Edge to moulded part (multiple surfaces) | 0,762 mm |

| Overmoulded part (multiple surfaces) | 0,762 mm |

| Bending angle | +/- 1° |

Possible component post-processing

Anodising, passivation, hard oxidation, powder coating, painting, plating, sandblasting, brushing

Advantages of Sheet Metal Fabrication

The sheet metal fabrication process is ideal for metal components and can support both prototyping and production quantities.

Multiple finishing options like anodizing and powder coating

Low material waste

Can cost-effectively scale to production volumes

Discover new possibilities

You can directly send the following data formats: Catia, NX, STEP, IGES, PRT, SLDPRT, DXF, and DWG.

We can convert CAD data formats so they are usable for production. Email:service@goldenrapid.com

Contact us

Get instant quotes for cost-effective solutions : From confidential design-to-product services to fast delivery, we empower innovators with precision and speed. Contact us now!

Phone: +86 0592 373 1111

E-mail: service@goldenrapid.com