Prototype and low-volume production in as fast as 1 day.

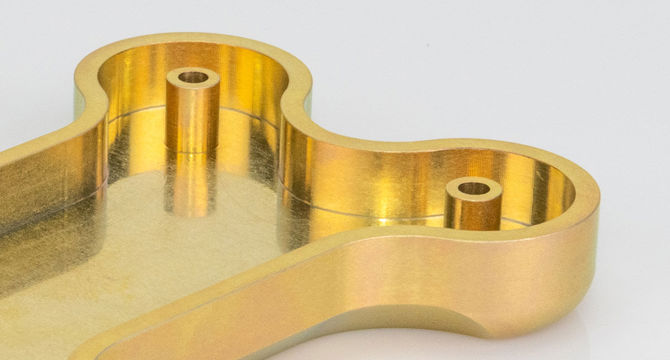

High-Precision CNC Machining For Complex Geometries And Tight Tolerances. Ideal For Prototypes, Fixtures, And Small-Batch Production Where Accuracy Matters.

Customizable Processes, Fast Lead Time, And Engineering-Grade Finishes.

Materials

Titanium, PEEK, Aluminum, Stainless Steel, POM, Etc.

Min. Parts Size & Max. Parts Size

Plastics : 520X1800x150mm

Metals : 580X1200x250mm

Ultra Precision CNC Machining

Coating and Plating Options:

- Anodizing

- Chromate coating

- Powder coating

- Zinc coating

- Nickle plating

Quick Turn(Mobile Phone Size)

- Simple1-2 Day

- Normal3 Day

- Complex5 Day

CNC Machining Capabilities

Our CNC machining centre is the solution for fast prototypes and small series production. We produce both complex prototypes and small batches of precision-manufactured parts.

Additional technologies such as thread cutting, drilling, eroding and wire cutting round off the production spectrum.

We also offer a range of other finishing options in the areas of surface technology, such as hard oxidation, passivation and chrome plating.

Processable metals

The metals that can be processed include aluminium, stainless steel, aluminium steels, bronze, brass, steel, titanium and carbon steel.

Processable plastics

Processable plastics include ABS, PC, PMMA, POM, PA, PP, PET, PVC, CPVC, PS, LDPE, HDPE, PSU, PPSU, nylon, PEEK, PEI and polycarbonates.

Tolerances

Our working methods are geared towards compliance with the ISO 2768 CNC machine standard. As a rule, the tolerances according to ISO 2768 (medium) and ISO 2768 (fine) are used. If tighter tolerances are required, a corresponding declaration in the drawings is necessary. Please contact us to discuss further options.

| Standards | Metal Part | Plastic Part |

| Max. Part Size | 1430×1130×450 mm | 1970×1470×250 mm |

| Min. Part Size | 1×1 mm | 2×2 mm |

| Min. Hole Size | Φ 0,30 mm | Φ 0,30 mm |

| Hole / Shaft Tolerance | H6/h6 | H7/h7 |

| Standard Tolerance | ISO 2768-f | ISO 2768-m |

| Min. Text CNC Engraving | Line Width 0,2 mm x Depth 0,3 mm | Line Width 0,2 mm x Depth 0,3 mm |

| Text Laser Engraving | Depth 0,05-0,1 mm | Depth 0,05-0,1 mm |

| Min. Milling Radius | Standard R 0,15 mm;Optional R 0,1 mm | Standard R 0,15 mm;Optional R 0,1 mm |

| Sirface Roughness Ra | PMMA Ra 0,04 – Ra 0,08;PC Ra 0,06 – Ra 1,0 |

The following should be noted with regard to the edge finish: The corners of the component are removed in the form of a chamfer or radius as shown in the drawing provided for the job. Specify the size of the resulting chamfer or radius.

Possible component post-processing

Surface treatment after machining changes the appearance, surface roughness, hardness and chemical resistance of the manufactured parts. This not only fulfils the functional requirements, but also protects and enhances the machined parts.

The following technologies are available for processing:

Anodising, grinding and polishing, bead blasting and anodising, water plating, steam polishing, passivation, hard oxidation, powder coating, painting, chrome plating, electrophoresis, electropolishing, sandblasting, heat treatment, brushing, electroplating

Discover new possibilities

Get in touch with us, describe your project and receive a quote and advice for the rapid production of your parts.Send the following data formats: Catia, NX, STEP, IGES, PRT, SLDPRT, DXF, and DWG. Email:service@goldenrapid.com

Contact us

Get instant quotes for cost-effective solutions : From confidential design-to-product services to fast delivery, we empower innovators with precision and speed. Contact us now!

Phone: +86 0592 373 1111

E-mail: service@goldenrapid.com